Luer Amatus (Lüer, Lueer), Paris

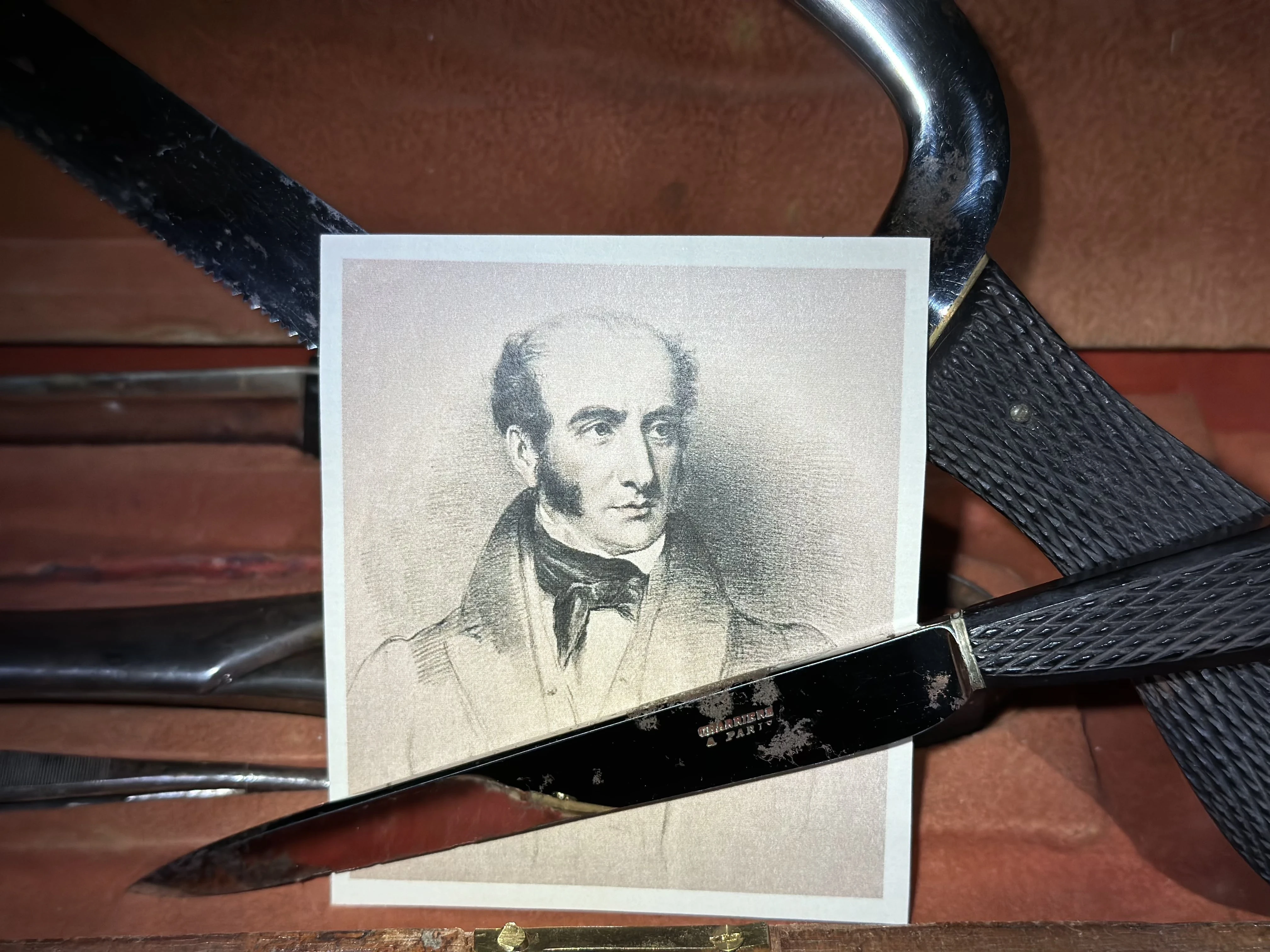

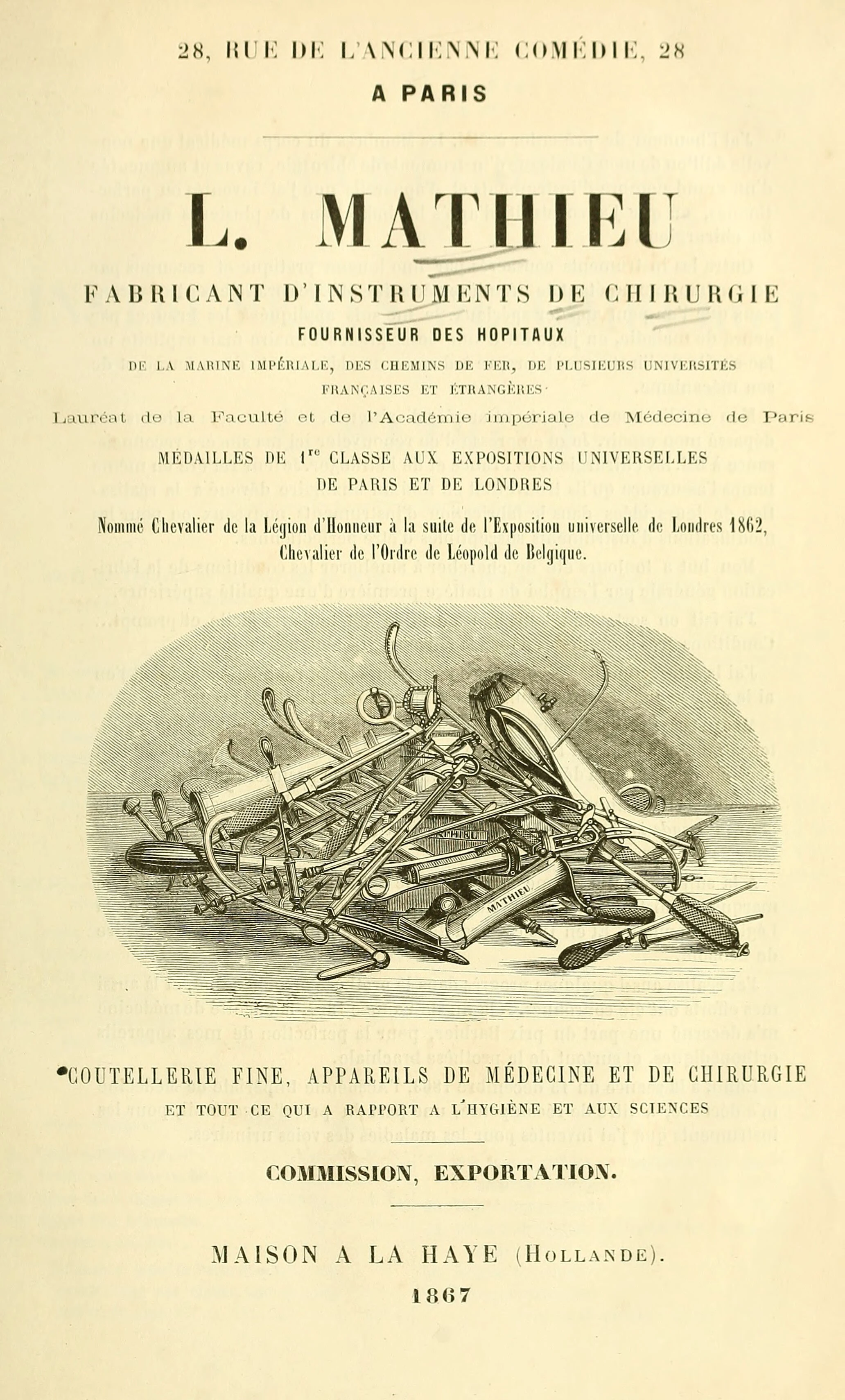

Lüer, Georg Wilhelm Amatus (born 6 April 1802 in Braunschweig and died on 20 February 1883 in Paris), German-born craftsman, arrived in Paris in 1830, where he joined the workshop of Swiss born Joseph-Frédéric-Benoêt Charrière. He demonstrated his high level of skill and was quickly promoted by his mentor, who entrusted him with the production of high-precision ophthalmic instruments. In 1837, Georg Amatus Lüer married Cäcilie Caroline (née Schaal, 1807–1870), who was originated from the same Swiss city as Charriére. In that year, together with his wife, they founded their own medical instruments company, Maison Lüer with the first address at 1 rue Crébillon, place de l'Odéon, Paris and later at 12 rue de l'Ecole de médecine, nearby to Maison Charrière.

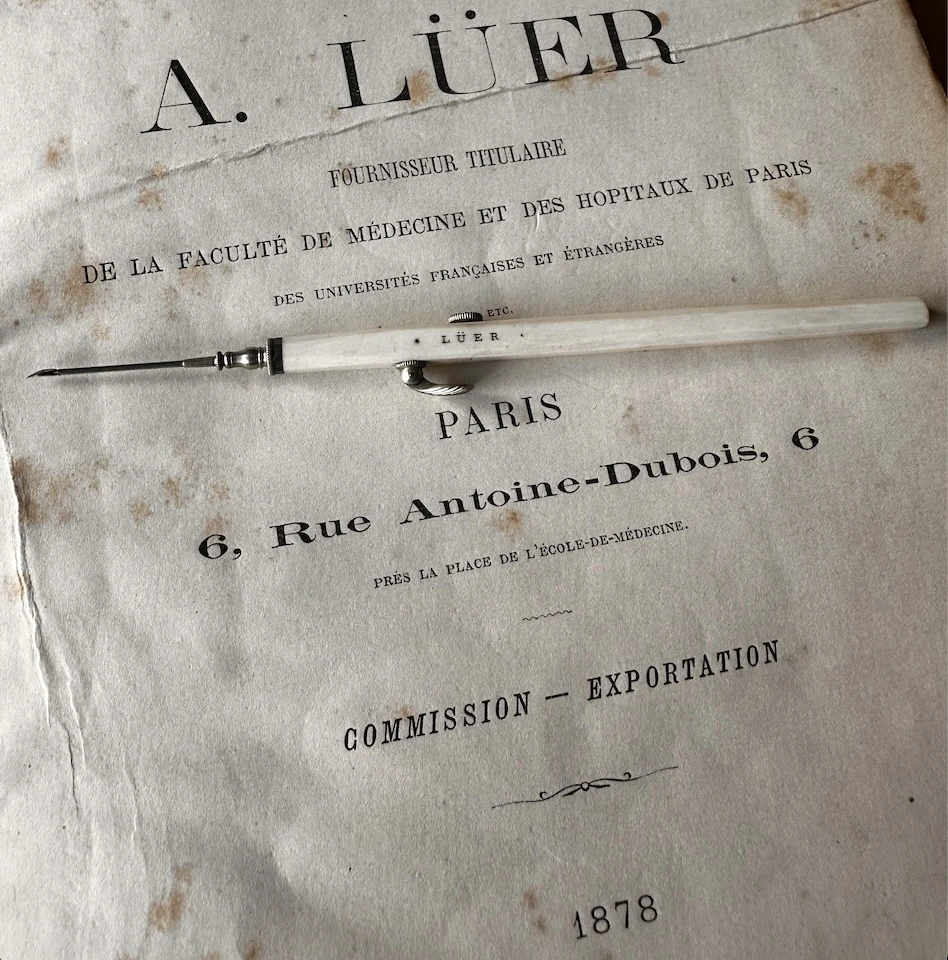

Initial years, he was specialized in the eye surgical instruments and later, around 1850 started producing instruments for otorhinolaryngology, urology, dentistry and gynecology also. In 1849 Lüer enlarged his activity and moved nearby — to the houses 3 and 19 at the Rue de l'Ecole de Médecine. In 1862 he became the Knight of Legion d'Honneur. However, in 1870 at the outbreak of the Franco-Prussian War (1870-1871) he was expelled from that address and had to move his workshop first to house 6 at Rue Antoine-Dubois (around the corner), and finally established himself at 104 Boulevard Saint-Germain (still very close to the School of Medicine). In 1881, two years before his death, Lüer was granted French citizenship under the name Georges-Guillaume-Amatus Lüer.

His daughter Jeanne Amélie (1842–1909) married Hermann Adolph Wülfing (1836–1910) from German city Barmen in 1867, who from then on used the double name Wülfing-Lüer. They inherited the Luer's business and continued further development of the company. Under Hermann Wülfing management the Maison Luer had patented an all-glass syringe for easy sterilization and precise dosage by 1897 and in 1904 obtained a US patent for this syringe. Although numerous surgical instruments bear the Lüer name, the most enduring legacy associated with it is the Luer-Lok system — a secure mechanism for attaching needles to syringes. Interestingly, this innovation was not developed by the original Lüer family but by Fairleigh S. Dickinson, co-founder of Becton Dickinson (BD), who patented the design in 1925.

On several cases and instruments, the name Lüer appears accompanied by the letters S.M. surmounted by a crown (S.M. for Sa Majesty) with a sometimes very elaborate design.

According to the official French commercial register (RCS Paris), the company “MAISON LUER” (SIREN 592 029 177), specializing in the manufacture of medical and surgical equipment in Paris, with address at 104 Boulevard Saint-Germain, Paris was removed from the RCS on September 7, 1993, after ceasing operations on June 15, 1993.

Addresses of Maison Lüer

1837. Foundation of the Lüer company at 1 rue Crébillon, place de l'Odéon, Paris

1841. At 12 rue de l'École de médecine, Paris (the same street as the shop of Charrière).

1849. Maison Lüer moved nearby an was located at 3 and 19 on rue de l'École de Médecine

1878, 1894. Address at 6, Rue Antoine-Dubois, 6 Paris "prés la Place de l'École de Médecine" (near the Place of The School of Medicine) — according to the catalogues dare 1878 and 1894

1912. Address at 104 Boulevard Saint-Germain, Paris – that address remained till the final closure of the company at 1993.

Luer-Lok fixation system

The invention of the Luer-Lok system consists of several stages. Doctors at that time used Pravaz syringes of rather complex design – made of glass, metal, and fabric gaskets (plunger) to ensure airtightness. For more accurate administration, the plunger rod had teeth onto which a stopper was screwed. The syringes did not withstand sterilization well, quickly lost their tightness, and, with frequent autoclaving, lost the graduations marked on the outer surface. The connection of the needles to the syringe barrel was also quite unreliable, and when the pressure in the system increased, the needles slipped off the cannula.

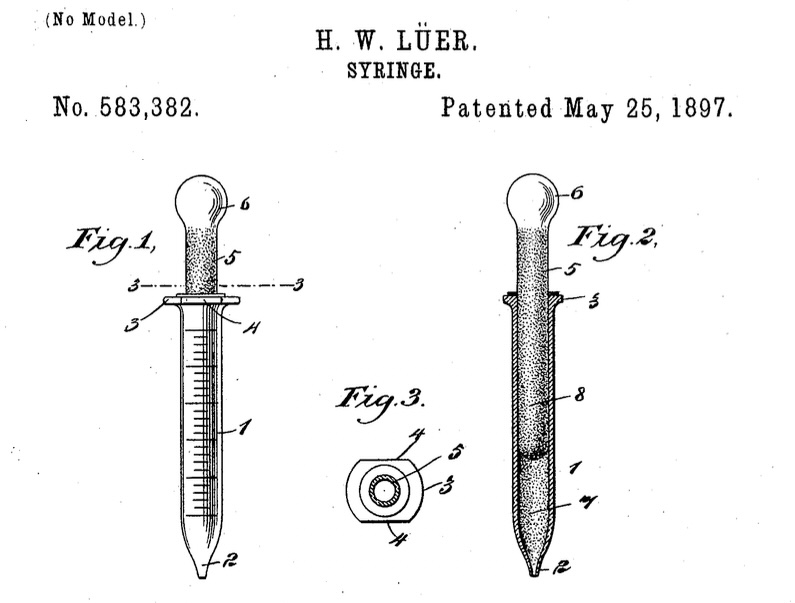

On November 6, 1894, Hermann Wülfing Lüer submitted a patent application for a "new system of an all-glass syringe especially intended for aseptic injections" (Nouveau système de seringue uniquement en verre et destinée spécialement aux injections aseptiques). This invention was granted French Patent No. 242,646 on February 16, 1895. Subsequently, Lüer secured patents for this syringe in several other countries: Germany (No. 88,352, April 20, 1895), Austria (No. 46/4136, November 4, 1895), England (No. 3,524, February 17, 1896), and the United States (US Patent No. 583,382, May 25, 1897). As it was written in the patent "a syringe comprising a glass cylinder having its interior surface ground from end to end, and a glass plunger operating in said cylinder, the said plunger having its body portion 70 ground on its exterior and having a length substantially equal to that of the cylinder." Another improvement was the design of the syringe tip proposed by Hermann Wülfing-Lüer — a conical cannula that narrowed by 6 degrees, ensuring both a tight fit of the needle and easy removal from the syringe. This innovative syringe design featured a ground-glass barrel and plunger, eliminating the need for additional sealing materials such as gaskets or lubricants. The precision fit between the components ensured an airtight seal, enhancing both sterility and durability. Its resistance to high-temperature sterilization processes, such as autoclaving, made it particularly suitable for aseptic medical procedures.

According to reports from the Biological Society, Paris; Proceedings and memoirs of an autumn meeting of 1894, with a report entitled “ALL-GLASS SYRINGE BY MR. WULFING-LUER” presented by Mr. Marassez. According to the published minutes, he said, in particular: "I had previously advised various manufacturers to try to make syringes made entirely of glass, including the plunger. This was an extremely difficult problem to solve in practice. However, Mr. Wulfing-Luër succeeded and asked me to present the following model to the Society. It is intended specifically for serotherapy, but can also be used for other types of injections. As you will notice, the body of the syringe is not a simple glass tube as found in commercial products; it has been ground internally with the greatest precision and its cavity is perfectly cylindrical. The piston and its rod, also made of glass, form a single, very regular cylindrical mass that fits smoothly into the body of the syringe... The tip of this syringe has also been ground very evenly, and the needle bellows fit it perfectly, forming another airtight seal. These syringes, made of special glass and annealed with great care, can withstand high temperatures without breaking; I have tested this. This new type of syringe therefore has great advantages: it is very simple, works admirably, and can be sterilized easily by all possible means. It is to be hoped that its construction will remain as meticulous as ever and that it will not be too expensive, so that it can become in common use."

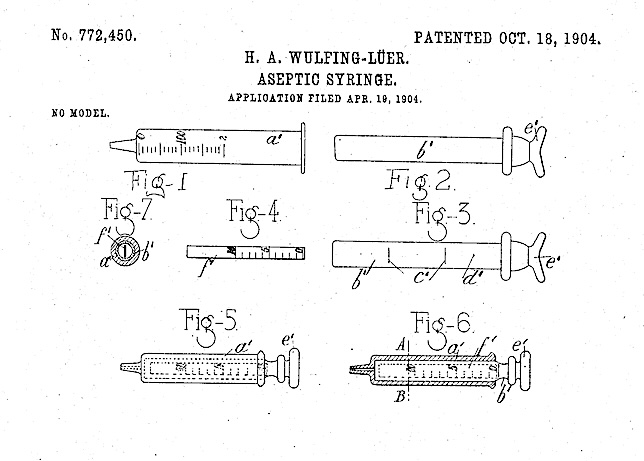

Later, in 1904 the next US patent followed (772,450). It claims that "At present the graduating of such a syringe is done by means of lines traced by acid on the exterior surface of 20 the body of the syringe, the plunger of such a syringe being entirely free from graduations. In order to sterilize the syringe before each injection, it is necessary to plunge it into water and bring this to a boiling-point, the result being that after a few operations the graduations become effaced and impossible to read." The additional graduation of the internal plunger are made by tiny grooves — this and other improvements of the company made usage of the syringe more easy and convenient.

In 1897, Maxwell W. Becton and Fairleigh S. Dickinson founded the Becton, Dickinson & Co (BD, headquartered in Franklin Lakes, NJ, USA), which would become one of America’s largest companies and producers of medical technology. Their first sale was a Lüer all-glass syringe — sold for US$2.50 in 1897. A year later in the subsequent 1898 they acquired a half interest in the Lüer’s American patent rights.

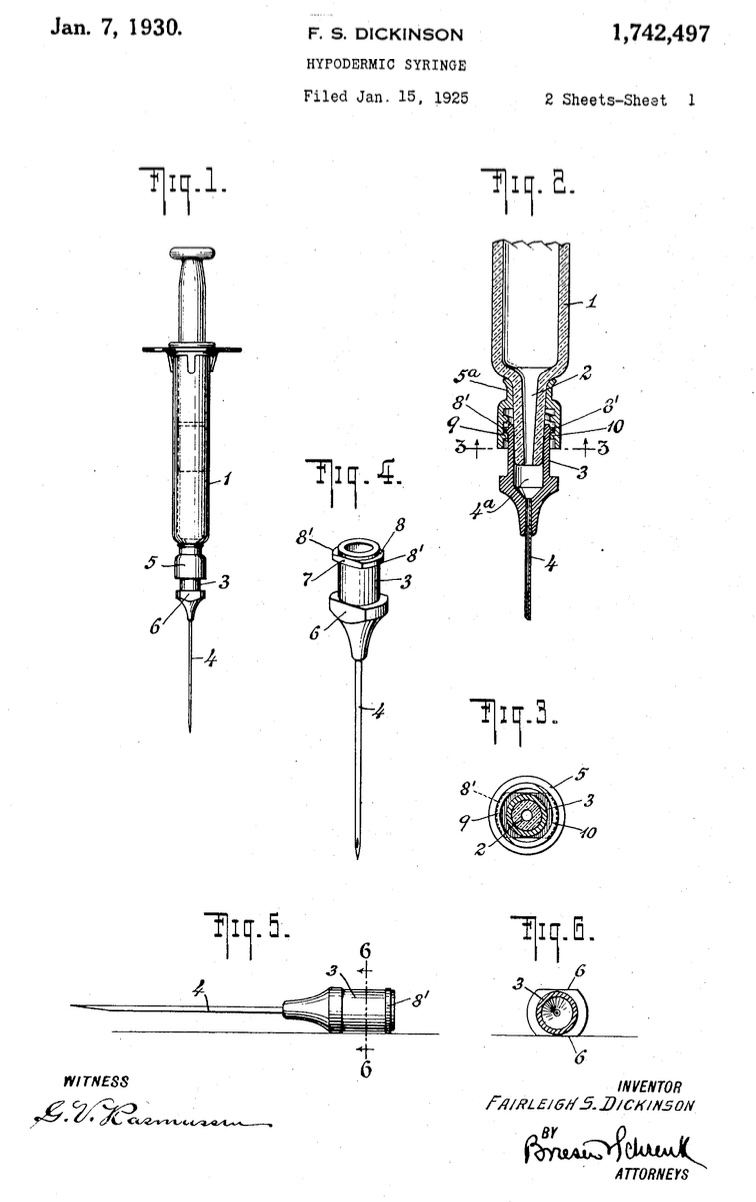

A significant advancement occurred in 1925 (approved five years later in 1930), when Fairleigh S. Dickinson, cofounder of Becton Dickinson, patented the Luer-Lok mechanism. This innovation addressed the issue of needles loosening under injection pressure. By incorporating locking flanges, the Luer-Lok allowed users to secure the needle to the syringe with a twist, engaging interlocking elements that prevented disconnection even under high pressure.

The Luer-Lok connection, which locks and unlocks with a twist and remains secure once engaged, quickly gained popularity due to its simplicity, reliability, and cost-effectiveness. Over time, the term "Luer" became generic; by around 1950, it was no longer capitalized except in references to historical or trademarked contexts. Today, this connection is regulated by the ISO 80369-1:2018 standard (Small-bore connectors for liquids and gases in healthcare applications) and the Luer design enables straightforward or functional connections between otherwise unrelated medical delivery systems, such as vascular, enteral, respiratory, epidural, and intrathecal devices, along with their components and accessories.

The Parisian instrument maker, Maison Lüer was one of the first in the world to make anesthesia apparatus. It was a direct competitor to Charrière, and several of the designs made by these companies are very similar to one another. One of these look-alikes is a metal dome that has a small compartment to hold a sponge soaked with chloroform. This allowed the patient to breathe the vapor while preventing the sponge from touching the patient’s face. Contact with liquid chloroform could cause irritation of the skin and mucous membranes.

The valves on the top and side of the inhaler were probably designed to allow in fresh air when the patient inhaled, and to guide the patient’s exhaled carbon dioxide away. The soft rim of the mask is made of kidskin and is stuffed with animal hair. This ensured a close, comfortable fit. Unlike later rim covers made of rubber, this was sewn on, and could not be replaced or sterilized.

This inhaler was described by Bouisson in his 1850 textbook, Traité théorique et pratique de la méthode anesthésique appliquée a la chirurgie et aux différentes branches de l'art de guérir. (Theory and practice of anesthesia applied to surgery and war.)

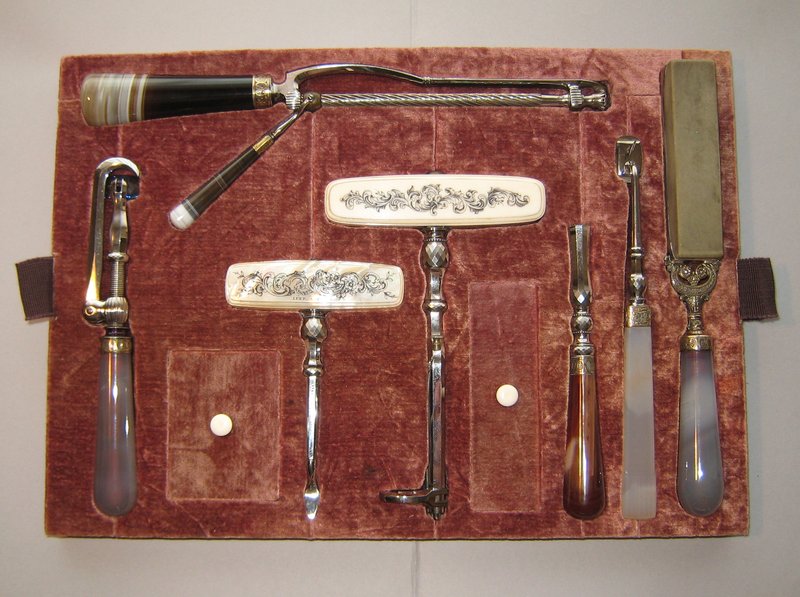

An example of his truly exceptional skill is a masterpiece of cutlery created for display at an international exhibition showcasing craftsmanship and technology. The quality of the steel, the high-end finish, the choice of different types of agate for the handles, and the refined aesthetics of their shapes, embellished with engraved vermeil ferrules and tips, make these instruments remarkable. It is difficult to obtain pieces large enough to make such handles. From the quartz stones family, Lüer succeeded to select carnelian, jasper, sardonyx, chalcedony, and banded agate. All the instruments are engraved with name of the company and the set can be dated to around 1850. The case is made of marquetry of thuja, ebony, rosewood, mahogany, and brass filet with an inlaid brass and mother-of-pearl motif. Inside the case there are two levels for the instruments. Below, the photos of the selected instruments are presented, more pictures one can find at the source ASPAD page.

The upper level of the dental instrumental case by Lüer (Ricci sounds, cleaning scalers with handles made of exceptionally transparent carnelian, cauters with agate handles, curettes, and a scalpel with red jasper handles). Source: ASPAD

The lower level of the dental instrumental case by Lüer (Carp tongue with mother-of-pearl handle, decorated with floral ornamentation, magnificent Garengeot key with ivory handle, hand drill, pelican, powder plug, triple diamond cut, carnelian handle). Source: ASPAD

Pull-out "pelican" key with adjustable lever on the shaft thread, handle made of chalcedony. Source: ASPAD

Carp tongue instrument with a mother-of-pearl handle adorned with engraved scrollwork, by Lüer. Source: ASPAD

An exceptional Dental drill holder with remarkable Archimedes screw drive shaft with twelve blades. Polished high-quality steel, adjustable reduction gear head, sardonyx handles decorated with gilded silver shells. Made by Lüer. Source: ASPAD

Eponyms

A large number of surgical instruments are named after Georges-Guillaume-Amatus Lüer:

- Luer curette

- Luer forceps

- Luer Inhaler

- Luer-Lok syringe, Luer needle, Luer syringe – see above

- Luer reconstruction plate

- Luer retractor

- Luer rongeur

- Luer scoop

- Luer speculum

- Luer suction cannula adapter

- Luer tracheal cannula

- Luer tube