Why Becton & Dickinson called its system Luer-Lok?

The 'Luer-Lok', a reliable needle connection system to the syringe barrel, was invented exactly one hundred years ago by Fairleigh S. Dickinson, one of the founders of Becton & Dickinson Inc. Today, this system is the global standard for connecting medical tubes, cannulas, needles and syringes. But why did an American company name its invention after the French instrument maker Maison Lüer?

Initial construction of hypodermic syringes

In the second half of 19th century, doctors used for hypodermic injections Pravaz syringes. They had rather complex design – made of glass, metal, and fabric gaskets (piston or plunger) to ensure airtightness, with the serrated plunger rod which a stopper was screwed to ensure more accurate drug administration. The syringes did not withstand sterilization well, quickly lost their tightness, and, with frequent autoclaving, lost the graduations marked on the outer surface. The connection of the needles to the syringe barrel was also quite unreliable, and when the pressure in the system increased, the needles slipped off the cannula.

Manufacturers of medical instruments understood these serious problems and constantly sought a solution. To prevent leakage of the medication and ensure accurate dosing, it was necessary to ensure the tightness of the moving system — the piston inside the syringe had to fit snugly against the inner walls of the bulb. This was achieved by a standard technological solution at the time — wrapping the plunger with a thread impregnated with a hydrophobic lubricant. However, this industrial solution was not suitable for medicine, especially during the emergence of antimicrobial theory and the introduction of autoclaving of instruments. This process quickly rendered the syringes unusable, causing them to lose their tightness.

One of the obvious solutions was to adjust the outer diameter of the piston and the inner diameter of the cylinder to each other and make their surfaces as smooth as possible, which would ensure the necessary tightness. The flask was traditionally made of glass, which allowed its contents to be observed and also withstood autoclave processing well, i.e., high temperatures, humidity, and pressure. It would be good to use it for the manufacture of both the flask and the piston. However, glass is an extremely hard material that is difficult to machine, and in this case, both the piston and the flask had to be manufactured with high precision and the interior had to be smooth.

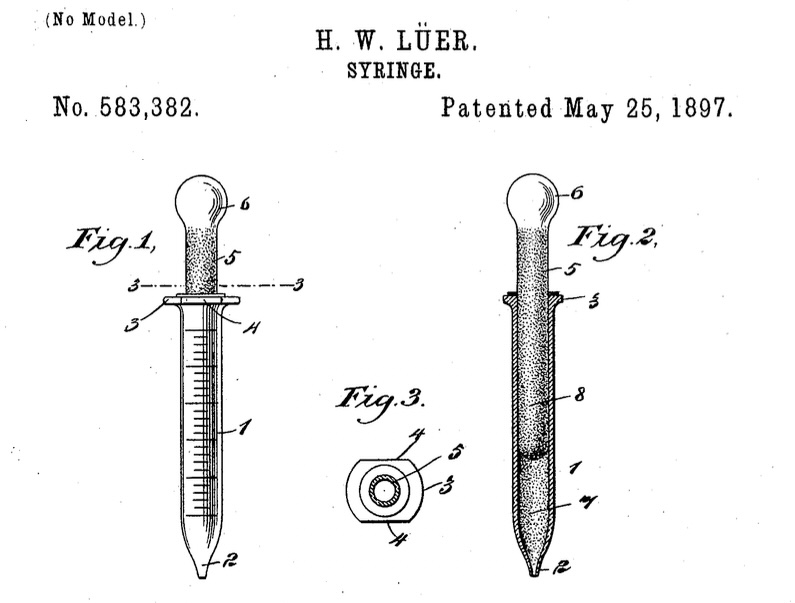

The head of the company Maison Lüer, Hermann Wülfing Lüer submitted a patent application for a "new system of an all-glass syringe especially intended for aseptic injections" (Nouveau système de seringue uniquement en verre et destinée spécialement aux injections aseptiques) on November 6, 1894. This invention was granted French Patent No. 242,646 on February 16, 1895. Subsequently, the company secured similar patents in other countries – Germany, Austria, England, and the United States.

Apparently, the specialists of famous French surgical instrument manufacturer have found innovative solution for the technological challenges. As it was written in the patent "a syringe comprising a glass cylinder having its interior surface ground from end to end, and a glass plunger operating in said cylinder, the said plunger having its body portion 70 ground on its exterior and having a length substantially equal to that of the cylinder."

Another improvement was the design of the syringe tip proposed by Hermann Wülfing-Lüer — a conical cannula that narrowed by 6 degrees, ensuring both a tight fit of the needle and easy removal from the syringe. This innovative syringe design featured a ground-glass barrel and plunger, eliminating the need for additional sealing materials such as gaskets or lubricants. The precision fit between the components ensured an airtight seal, enhancing both sterility and durability. Its resistance to high-temperature sterilization processes, such as autoclaving, made it particularly suitable for aseptic medical procedures.

According to reports from the Biological Society, Paris; Proceedings and memoirs of an autumn meeting of 1894, with a report entitled “ALL-GLASS SYRINGE BY MR. WULFING-LUER” presented by Mr. Marassez. According to the published minutes, he said, in particular:

"I had previously advised various manufacturers to try to make syringes made entirely of glass, including the plunger. This was an extremely difficult problem to solve in practice. However, Mr. Wulfing-Luër succeeded and asked me to present the following model to the Society... As you will notice, the body of the syringe is not a simple glass tube as found in commercial products; it has been ground internally with the greatest precision and its cavity is perfectly cylindrical. The piston and its rod, also made of glass, form a single, very regular cylindrical mass that fits smoothly into the body of the syringe... The tip of this syringe has also been ground very evenly, and the needle bellows fit it perfectly, forming another airtight seal. These syringes, made of special glass and annealed with great care, can withstand high temperatures without breaking; I have tested this. This new type of syringe therefore has great advantages: it is very simple, works admirably, and can be sterilized easily by all possible means. It is to be hoped that its construction will remain as meticulous as ever and that it will not be too expensive, so that it can become in common use." (Weekly proceedings of the Society of Biology, Paris, 3th of November, 1894, p. 689)

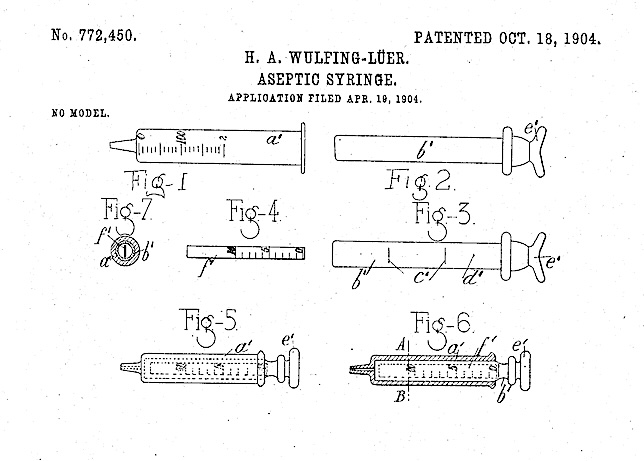

Later, in 1904 the next US patent followed (772,450). It claims that "At present the graduating of such a syringe is done by means of lines traced by acid on the exterior surface of 20 the body of the syringe, the plunger of such a syringe being entirely free from graduations. In order to sterilize the syringe before each injection, it is necessary to plunge it into water and bring this to a boiling-point, the result being that after a few operations the graduations become effaced and impossible to read." The additional graduation of the internal plunger are made by tiny grooves — this and other improvements of the company made usage of the syringe more easy and convenient.

This innovation was of tremendous importance. Now, doctors have a reliable and safe product for parenteral drug administration. This achievement was recognised and celebrated by the International Jury of the World's Universal Exhibition in Paris, France in 1900 (Reports of the International Jury, World's Fair, Paris: 1900, p. 465): "Next to the Collin house, Mr. Mathieu, together with Mr. Wülfing-Luer, are among our best manufacturers of surgical instruments. High-level degrees have been awarded for many years of work and industrial loyalty, as well as for an active understanding of the needs of modern surgery... Mr. Wülfing-Luer has gained universal renown for the manufacture of instruments for eye surgery and for the manufacture of large razors; he manufactures a glass-piston syringe that is a masterpiece of craftsmanship... Noting the care that Messrs. Collin, Mathieu, and Wülfing-Luer take in their manufacturing, we cannot urge them enough to make new and continuous efforts to maintain the superiority of French manufacturing and to always prove themselves worthy of their reputation."

In tribute to the collective input of the company's many specialists, it should be noted that this innovation was not the work of Wülfing-Luer alone, but was supported by several of his talented craftsmen. The jury also recognised their contribution: "We awarded a silver medal for collaboration to Mr. G. Fournier, glassblower, whose talent contributed greatly to the manufacture of the glass syringe; Mr. Moria, who has been working with Mr. Wülfing-Luer for eight years, received a bronze medal." (ibid).

In 1897, Maxwell W. Becton and Fairleigh S. Dickinson founded the Becton, Dickinson & Co (BD, headquartered in Franklin Lakes, NJ, USA), which would become one of America’s largest companies and producers of medical technology. Their first sale was a Lüer all-glass syringe — sold for US$2.50 in 1897. A year later in the subsequent 1898 they acquired a half interest in the Lüer’s American patent rights.

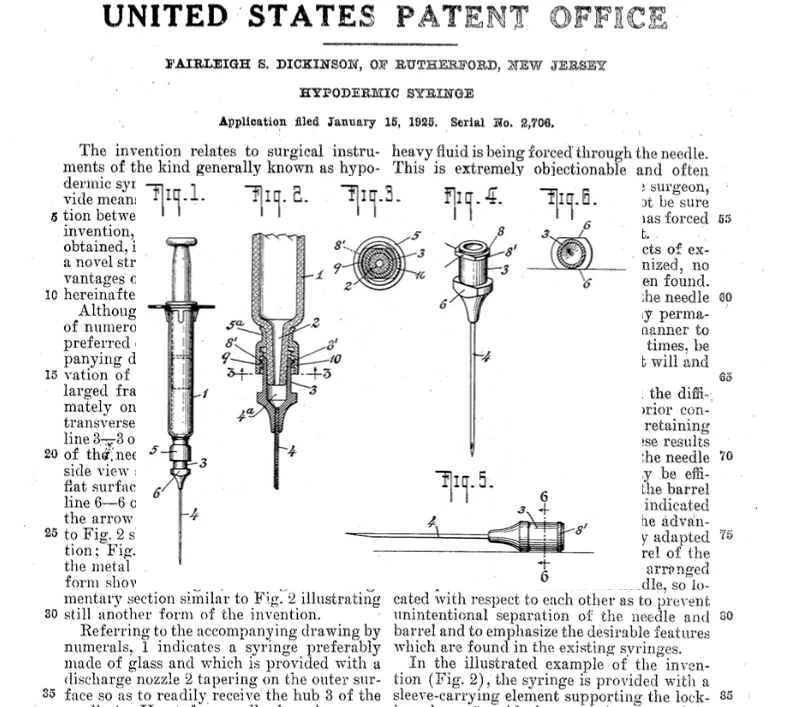

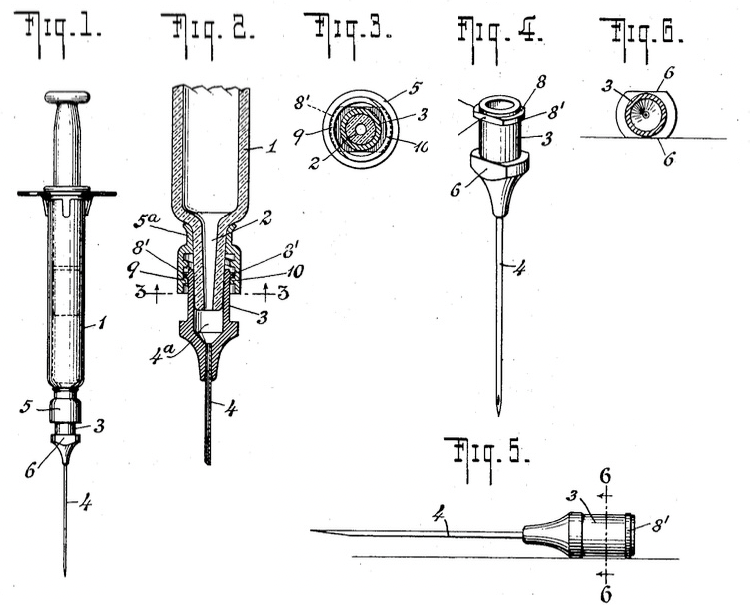

A significant advancement occurred in 1925 when Fairleigh S. Dickinson, cofounder of Becton Dickinson, applied to the patent of the Luer-Lok mechanism (approved five years later in 1930). This innovation addressed the issue of needles loosening under injection pressure. By incorporating locking flanges, the Luer-Lok allowed users to secure the needle to the syringe with a twist, engaging interlocking elements that prevented disconnection even under high pressure.

By that time, the Luer syringe was already very well known in the US and around the world, so it would have been unwise to abandon such a recognisable brand and miss out on a marketing opportunity. Adding the word 'Lok' (with the spelling of 'Lock' simplified and the German diaeresis removed from 'Lüer') symbolised the product's even greater advantages and reliability. As we now know from the successful development of Becton & Dickinson, which turned into the medical industry giant BD a hundred years later, this idea proved to be a brilliant one.

The Luer-Lok connection, which locks and unlocks with a twist and remains secure once engaged, quickly gained popularity due to its simplicity, reliability, and cost-effectiveness. Over time, the term "Luer" became generic; by around 1950, it was no longer capitalized except in references to historical or trademarked contexts. Today, this connection is regulated by the ISO 80369-1:2018 standard (Small-bore connectors for liquids and gases in healthcare applications) and the Luer design enables straightforward or functional connections between otherwise unrelated medical delivery systems, such as vascular, enteral, respiratory, epidural, and intrathecal devices, along with their components and accessories.